Groente-, fruit- en tuinafval: het begin van iets moois

Groente-, fruit- en tuinafval is veel meer dan alleen compost. Dat laat Grondstoffen- en energiebedrijf Meerlanden zien in zijn Groene Energiefabriek in Rijsenhout, net onder Schiphol. Daar wordt het gft-afval van negen gemeenten en 4.000 bedrijven uit de regio verwerkt tot groengas, CO2, warmte, compost, citrusbrandstof en water.

In 2010 gooide Grondstoffen- en energiebedrijf Meerlanden het roer om: het bedrijf wilde de afvalstroom gft beter gaan benutten. Daartoe werd eerst veel onderzoek gedaan. Meerlanden verzamelde best practices in heel Europa en de onderzoekers kozen van alle technieken die ze tegenkwamen degene die het beste gecombineerd konden worden in de Groene Energiefabriek. De afvalverwerker werkte in deze fase nauw samen met specialisten op het gebied van procestechniek en circulariteit. In 2011 werd de Groene Energiefabriek gebouwd.

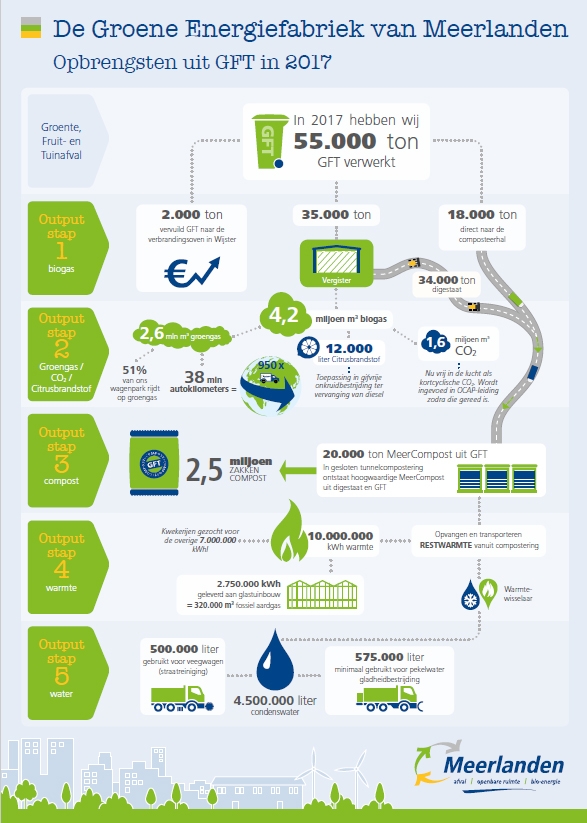

In die fabriek wordt het groente-, fruit- en tuinafval in vijf stappen verwerkt, waarbij elke stap output oplevert. In een speciale vergister, van Zwitserse makelij, wordt 53.000 ton van de binnenkomende 55.000 ton gft-afval circulair verwerkt. Zestig procent van het gft-afval wordt biogas dat wordt opgewaardeerd tot groengas. Dat dient als brandstof voor meer dan de helft van het wagenpark van Meerlanden. Het overige deel vindt zijn weg naar de huishoudens en industrie in de omgeving. Uit het biogas wordt de CO2 afgevangen. Dat gaat naar verschillende glastuinbouwbedrijven die het als groeiverbeteraar gebruiken. Sinds kort past Meerlanden ook een techniek toe om de olie uit citrusschillen te halen. Die brandstof wordt nu in plaats van diesel gebruikt in de onkruidbestrijdingsapparatuur van Meerlanden zelf.

Compost en warmte

Het innovatieve tunnelcomposteersysteem zorgt voor 2,5 miljoen zakken compost. De warmte die tijdens dat proces vrijkomt wordt voor een groot deel afgevangen, in totaal zo’n 10 miljoen kWH. Meer dan een kwart daarvan gaat naar een nabijgelegen glastuinbouwbedrijf, dat hierdoor 320.000 m3 minder fossiel aardgas hoeft te stoken. Tijdens het composteren ontstaat er ook condens. De 4,5 miljoen liter condenswater wordt onder meer gebruikt voor gladheidsbestrijding en straatreiniging.

Meerlanden onderzoekt of het nog meer kan halen uit de 55.000 ton gft die het jaarlijks binnenkrijgt. Zo loopt er onder meer een project om nog meer warmte te benutten en wordt onderzocht of er ook andere grondstoffen uit het gft-afval terug te winnen zijn. Denk bijvoorbeeld aan vezels die voor de papierindustrie interessant kunnen zijn en vetzuren voor de chemische productie van biobased materialen.

Investeringen terugverdienen

Wanneer er een methode gevonden is om extra grondstoffen te onttrekken aan het gft wordt er direct nagedacht over de eventuele afnemer van deze grondstoffen, waarmee vervolgens contact wordt gezocht. Die samenwerking met bedrijven in de regio en gemeenten vormt het fundament van het succes van de Groene Energiefabriek tot nu toe: ze laten zien dat er wel degelijk vraag is naar de output van de fabriek.

De investeringen die Meerlanden deed en doet verdienen zich uiteraard niet van de ene op de andere dag terug. Er is financiële steun van de gemeenten waarin Meerlanden actief is. Ook krijgt Meerlanden van het Rijk de subsidie Stimulering Duurzame Energieproductie (SDE+). Daarnaast zijn er inkomsten uit de verkoop van het groengas, CO2, warmte, compost en water of ten minste besparingen wanneer ze intern worden gebruikt.

Burgers betrekken

Ook burgers in de regio worden betrokken bij de fabriek. Meerlanden ontwikkelde het platform Begin van iets moois om te laten zien wat er allemaal met het afval van burgers in de regio wordt gedaan. Zo hoopt de organisatie naast bedrijven ook burgers te stimuleren om hun afval nog beter te scheiden.

Gft-afval in de Metropoolregio Amsterdam en de rest van Nederland

Meerlanden verwerkt afval in negen gemeenten in de omgeving van Schiphol, de Bollenstreek en Zuid-Kennemerland. Volgens de Grondstoffenatlas van de Metropoolregio Amsterdam zit in de regio het merendeel van het gft nog in het restafval. Dat komt voor een belangrijk deel doordat in de stad Amsterdam gft-afval nauwelijks gescheiden wordt ingezameld. Wel zijn er lokale initiatieven en verschillende pilots, zoals stadscompost.nl, de plaatsing in 2017/2018 van 45 zogenaamde wormenhotels in de stad en de gfe-inzameling (groente, fruit en etensresten) sinds 2016 op Java-eiland, die werd ingevoerd samen met een aantal gemotiveerde bewoners en ondernemers (opbrengst 58 ton gfe in 2017).

Dit jaar nog wordt ook op een deel van IJburg (Steigereiland) gestart met gfe-inzameling, op verzoek van de IJburgers zelf. Medio 2019 is deze inzameling op het hele eiland gerealiseerd. Als de resultaten op IJburg goed zijn — tenminste 30 procent doet mee — dan is het voornemen de gfe inzameling in het Oostelijk Havengebied en de Oostelijke Eilanden in 2020 op te pakken. In Zuidoost wordt onderzocht of de huishoudens die een minicontainer gebruiken voor hun restafval, er in 2019 ook een voor gfe en tuinafval kunnen krijgen.

Het nu ingezamelde gfe in Amsterdam wordt tot 5 producten verwerkt: er wordt biogas uitgehaald, waar vrachtwagens op rijden. Restwarmte en vastgelegde CO2 worden geleverd aan de tuinbouw, water wordt benut bij gladheidsbestrijding van de wegen en de compost wordt als keurcompost verkocht aan de landbouw. Ook zijn er veel nieuwe gfe-toepassingen in ontwikkeling zoals kleding van groente- en fruitvezels en nutriënten voor veevoer en de potentie is groot.

In navolging van de Groene Energiefabriek van Meerlanden hebben andere afvalverwerkers vergelijkbare initiatieven ontplooid, goede voorbeelden hiervan zijn HVC in Middenmeer en Indaver in Alphen aan den Rijn.

Scherpe doelen

Op deze pagina van de Vereniging Afvalbedrijven staan verschillende goede voorbeelden van succesvolle gft-maatregelen.

Lees meer

Dit is deel 7 uit een reeks aan artikelen over het grondstoffentransitieprogramma in de Metropoolregio Amsterdam.

- Bekijk hier artikel 1: Half miljoen dataservers jaarlijks afgedankt in Nederland

- Bekijk hier artikel 2: Hoogwaardige verwerking van voedselresten

- Bekijk hier artikel 3: Bermgras als groene grondstof

- Bekijk hier artikel 4. E-waste hergebruiken

- Bekijk hier artikel 5: Start hergebruik van miljoenen luiers

- Bekijk hier artikel 6: Van afgedankt textiel naar nieuwe garens

Rol van de Board

De Amsterdam Economic Board staat aan de wieg van deze ontwikkelingen door gedegen marktverkenning en introducties tussen betrokken partijen in het kader van het grondstoffen uitvoeringsprogramma van de Board. Dit is het samenwerkingsprogramma waar afvalstromen zoals textiel op schaal van de Metropoolregio Amsterdam gebundeld en opgewaardeerd worden tot nieuwe grondstofstromen.

11 december 2018

Meer weten over

Neem contact op

Blijf jij ook op de hoogte?

8x per jaar nieuws en events uit de regio: schrijf je in voor de Board Update nieuwsbrief

Deel dit artikel

Wil je op de hoogte blijven?

Volg ons dagelijks op LinkedIn en schrijf je in voor de Board Update nieuwsbrief.

Lees ook deze berichten

- Met de Learn & Share-serie Scaling up Startups brengen we professionals uit ...

- Incision is gekozen als de finalist voor de Nationale Zorginnovatieprijs 2026! Dit innovatieve ...

- Een nieuwe lichting gedreven jongeren is aangetreden bij Young on Board, de ...